The intelligent warehousing system integrates with the ERP system, MES system, etc., to accurately realize the distribution of work order materials according to the station information; the SMT intelligent warehousing system and the placement machine data interconnection, realize the automatic data of the end of the production line when the materials are returned to the warehouse Update

Comparison between traditional and smart models

Disadvantages of the traditional model: Work order preparation information is transmitted through paper documents. It is difficult for preparation personnel to prepare materials according to the rules of first-in, first-out, tailings priority, etc., and it takes a lot of manpower to count the tailings back to the warehouse.

Intelligent material warehousing logistics model

The SMT intelligent warehousing system can intelligently and unmannedly realize a series of circulation actions of materials from the warehouse to the production line, such as storage, picking, distribution, verification, and delivery. According to the real-time demand of the production line, the materials are automatically removed from the warehouse and arrive at the production line. Tailings are automatically counted and returned to the warehouse

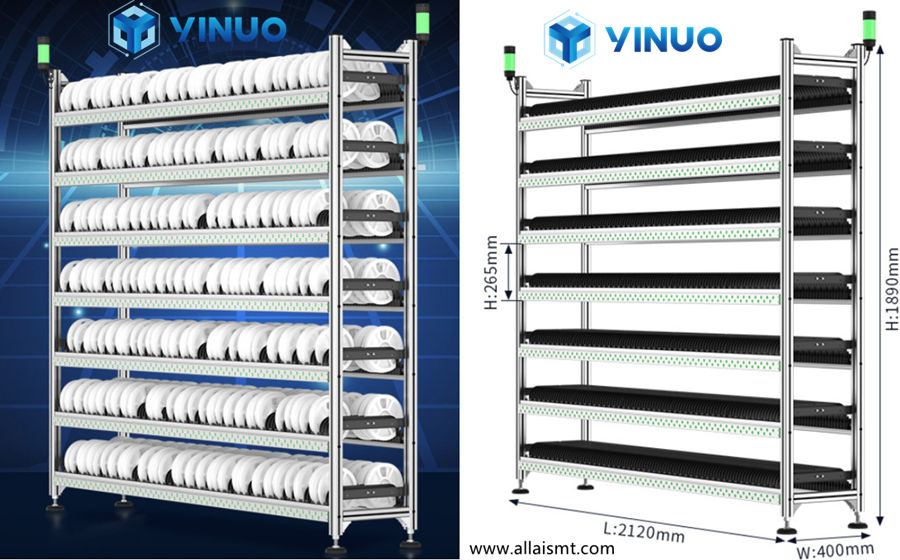

The SMT intelligent material rack is suitable for SMT warehouses and on-line feeding and replenishment. The material rack TAB PC and lithium battery can be used as a mobile warehouse. The material rack is equipped with a lighting system, and the docking with the MES system greatly saves the time for system work orders. , The operator is easy to operate and can quickly and accurately find the required materials.