Label Feeders: The Key to Accurate Product Labeling

In the world of manufacturing and packaging, accurate labeling is crucial. It ensures that products are properly identified, enhances brand visibility, and complies with regulatory requirements. One of the critical components in achieving accurate product labeling is the label feeder. This device plays a pivotal role in automating the labeling process, making it faster, more precise, and efficient.

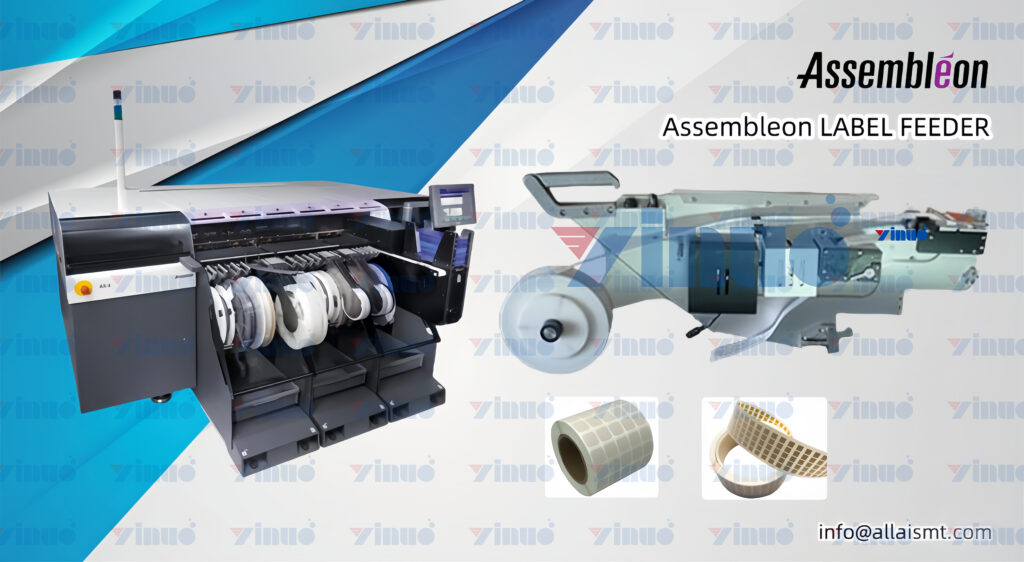

What are Label Feeders?

Label feeders are specialized devices used in automated labeling systems. They are designed to dispense labels at high speeds and with great accuracy, ensuring that each label is applied to the correct position on a product. These feeders can handle a variety of label types, including self-adhesive, pressure-sensitive, and RFID labels. The primary function of a label feeder is to ensure a continuous supply of labels to the labeling machine, minimizing downtime and maximizing productivity.

Types of Label Feeders

There are several types of label feeders, each suited to different applications and industries:

- Roll Feeders: These feeders use rolls of labels and are ideal for high-volume production lines. They can accommodate large label rolls, reducing the need for frequent roll changes.

- Sheet Feeders: Sheet feeders are used for labels that come in sheets rather than rolls. They are often used in smaller production runs or for specialty labels.

- Print-and-Apply Feeders: These feeders combine label printing and application in a single process. They are commonly used for variable data labeling, such as barcodes and serial numbers.

- RFID Label Feeders: These feeders handle RFID labels, which are used for inventory tracking and security purposes. They ensure precise placement of RFID tags, which is critical for their functionality.

The Importance of Accuracy in Labeling

Accuracy in labeling is paramount for several reasons:

- Compliance: Many industries are subject to strict labeling regulations. Inaccurate labeling can lead to regulatory fines and recalls, which can be costly and damaging to a brand’s reputation.

- Brand Integrity: Consistent and accurate labeling helps maintain brand integrity. Mislabeling can confuse customers and lead to a loss of trust in the brand.

- Operational Efficiency: Accurate labeling reduces the risk of errors in the supply chain. It ensures that products are correctly identified and tracked throughout the distribution process.

- Consumer Safety: Inaccurate labeling of products, especially in the food, pharmaceutical, and chemical industries, can pose serious health risks to consumers.

Benefits of Using Label Feeders

Implementing label feeders in a production line offers several benefits:

- Increased Speed and Efficiency: Label feeders automate the labeling process, significantly increasing the speed of production lines and reducing manual labor.

- Enhanced Precision: Modern label feeders are equipped with advanced sensors and control systems that ensure precise label placement, even at high speeds.

- Reduced Downtime: With features like automatic roll change and continuous label supply, label feeders minimize downtime, keeping production lines running smoothly.

- Cost Savings: Automation reduces the need for manual intervention, leading to cost savings in labor and reducing the likelihood of costly labeling errors.

Choosing the Right Label Feeder

Selecting the appropriate label feeder for a specific application depends on several factors:

- Label Type: Different feeders are designed for different types of labels. It’s essential to choose a feeder that matches the label type used in the production process.

- Production Volume: High-volume production lines require feeders that can handle large rolls and operate at high speeds without frequent interruptions.

- Application Environment: The environment in which the label feeder will operate is crucial. For example, feeders used in food and pharmaceutical industries must comply with hygiene and safety standards.

- Integration Capabilities: The label feeder should be compatible with existing production line equipment and control systems for seamless integration.

Conclusion

Label feeders are indispensable tools in modern manufacturing and packaging processes. They ensure that labeling is carried out with precision and efficiency, enhancing compliance, brand integrity, and operational efficiency. By choosing the right label feeder and integrating it into the production line, manufacturers can achieve accurate product labeling, reduce errors, and ultimately improve overall productivity. In an era where accuracy and efficiency are paramount, label feeders are indeed the key to accurate product labeling.