The Advantages of Using Label Feeders in Production

In the competitive world of manufacturing, efficiency, precision, and consistency are key to maintaining a competitive edge. Among the various tools and technologies that have revolutionized production processes, label feeders stand out as essential components. These automated systems, designed to apply labels to products and packaging, offer numerous advantages that significantly enhance production capabilities. This article delves into the primary benefits of using label feeders in production.

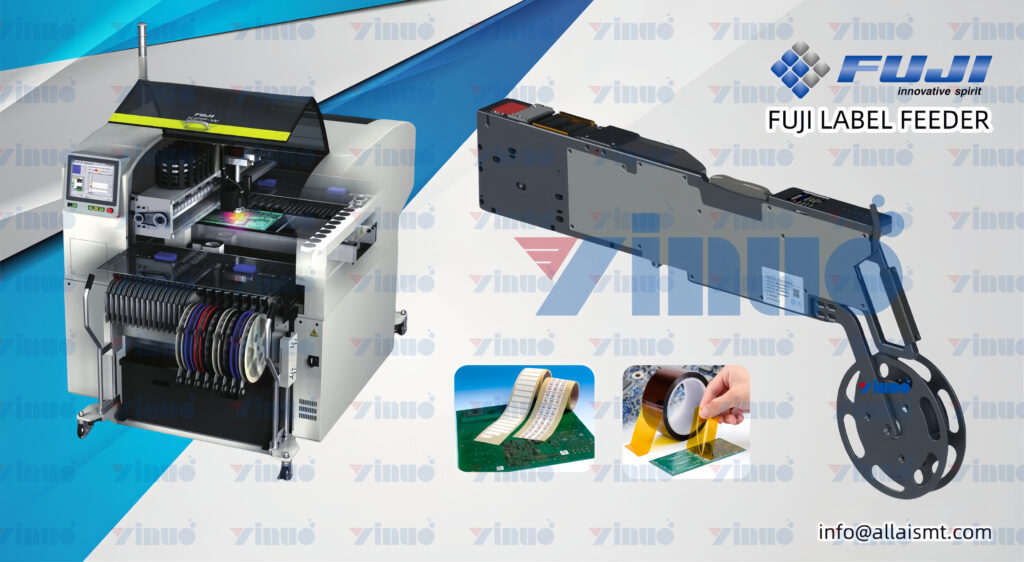

What Are Label Feeders?

Label feeders are automated devices integrated into production lines to apply labels to products or packaging consistently and accurately. They are widely used in industries such as electronics, pharmaceuticals, food and beverage, and consumer goods. By automating the labeling process, label feeders help manufacturers improve efficiency, reduce errors, and maintain high-quality standards.

Advantages of Using Label Feeders

1. Enhanced Production Efficiency

a. Increased Speed

Label feeders can apply labels much faster than manual processes, significantly increasing production speed. This is particularly important in high-volume production environments where time is a critical factor. Automated labeling ensures that the production line keeps moving without bottlenecks caused by slow or inconsistent manual labeling.

b. Continuous Operation

Unlike human labor, label feeders can operate continuously without breaks, maintaining a steady pace of production. This continuous operation maximizes uptime and throughput, leading to higher overall productivity.

2. Improved Accuracy and Consistency

a. Precision Label Application

Label feeders use advanced sensors and control systems to apply labels with high precision. This ensures that each label is correctly positioned, oriented, and affixed, reducing the likelihood of misaligned or improperly placed labels.

b. Uniformity Across Products

Consistency in labeling is essential for maintaining product quality and brand integrity. Label feeders ensure that every product is labeled in the same manner, providing a uniform appearance that meets regulatory standards and customer expectations.

3. Reduced Human Error

Manual labeling is prone to errors due to fatigue, distractions, and variability in skill levels. Label feeders eliminate these issues by automating the process, thereby significantly reducing the chances of errors. This leads to higher accuracy and consistency, which are crucial for maintaining product quality and compliance.

4. Cost Savings

a. Lower Labor Costs

By automating the labeling process, manufacturers can reduce their reliance on manual labor, leading to significant cost savings. The initial investment in label feeders is offset by the reduction in labor costs over time.

b. Minimized Waste

Accurate and consistent labeling reduces the likelihood of errors that can lead to waste. Misapplied or incorrect labels often result in the need for rework or disposal of the affected products, increasing costs and resource wastage. Label feeders help minimize these issues by ensuring that labels are applied correctly the first time.

5. Enhanced Product Quality

a. Compliance with Standards

Industries such as pharmaceuticals and food and beverage have stringent labeling requirements to ensure safety and compliance. Label feeders help manufacturers meet these standards by providing precise and consistent labeling, reducing the risk of non-compliance.

b. Improved Customer Satisfaction

Well-labeled products not only comply with regulations but also meet customer expectations for quality. Accurate and professional labeling enhances the overall appearance of products, contributing to improved customer satisfaction and brand loyalty.

6. Flexibility and Scalability

a. Adaptability to Various Products

Modern label feeders are designed to handle a wide range of label types, sizes, and materials, making them versatile tools in the production process. This adaptability allows manufacturers to use the same labeling equipment for different products, reducing the need for multiple labeling systems.

b. Scalable Solutions

As production demands increase, label feeders can be scaled to accommodate higher volumes without compromising accuracy or efficiency. This scalability makes them a valuable asset for growing businesses looking to expand their production capabilities.

7. Data Integration and Traceability

Advanced label feeders can be integrated with production management systems, enabling real-time data tracking and traceability. This integration allows manufacturers to monitor the labeling process, track production metrics, and ensure traceability for quality control and regulatory compliance.

Conclusion

Label feeders are invaluable tools in modern manufacturing, offering numerous advantages that enhance production efficiency, accuracy, and consistency. By automating the labeling process, these devices reduce human error, ensure uniformity, and apply labels with high precision. The benefits of using label feeders extend beyond improved labeling – they contribute to cost savings, enhanced product quality, and the ability to scale production. As technology continues to advance, label feeders will play an increasingly critical role in driving innovation and maintaining competitive advantage in the manufacturing industry.