The pcba processing factory tells you what are the precautions for PCB jigsaw

The following Dongguan pcba processing plant first lists 10 requirements for attention, welcome everyone to correct:

1. The outer frame (clamping side) of the PCB jigsaw should use closed-loop planning to ensure that the PCB jigsaw will not be deformed in the future when fixed on the fixture;

2, the width of the PCB panel is ≤260mm (SIEMENS line) or ≤300mm (the FUJI line); if active dispensing is required, the width of the PCB panel is ≤125 mm × 180 mm;

3. The shape of PCB jigsaw should be as close as possible to a square. It is recommended to use 2×2, 3×3…

4. The center distance between the small plates is controlled between 75 mm and 145 mm;

5. When setting the reference positioning point, usually leave a non-resistance area 1.5 mm larger than it around the positioning point;

pcba processing

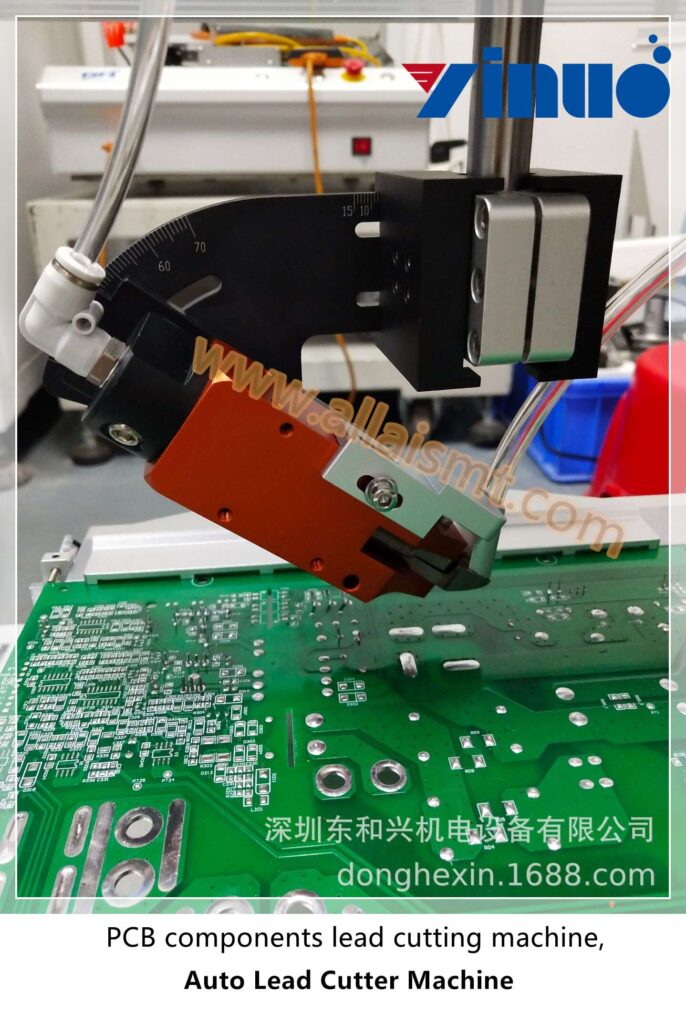

6. There should be no large devices or protruding devices near the connection points between the outer frame of the panel and the inner small board, and between the small board and the small board, and there should be a space greater than 0.5mm between the components and the PCB board. To ensure the normal operation of the cutting tool;

7. Four positioning holes are made in the four corners of the frame of the jigsaw, with a diameter of 4mm±0.01mm; the strength of the holes should be moderate to ensure that there will be no cracks during the upper and lower boards; the precision of the hole diameter and position should be high, and the hole wall should be lubricated and free of burrs. ;

8. Each small board in the PCB jigsaw must have at least three positioning holes, 3≤aperture ≤6 mm, and no wiring or patching within 1mm of the marginal positioning hole;

9. The reference symbols used for the positioning of the entire PCB and the positioning of fine-pitch devices. In principle, the QFP with a pitch less than 0.65mm should be set in its diagonal position; the positioning reference symbols used for the imposition PCB sub-board should be paired Used, arranged at the opposite corner of the positioning element;

10. Large components should have positioning posts or positioning holes, such as I/O interface, microphone, battery interface, micro switch, headphone interface, motor, etc.;