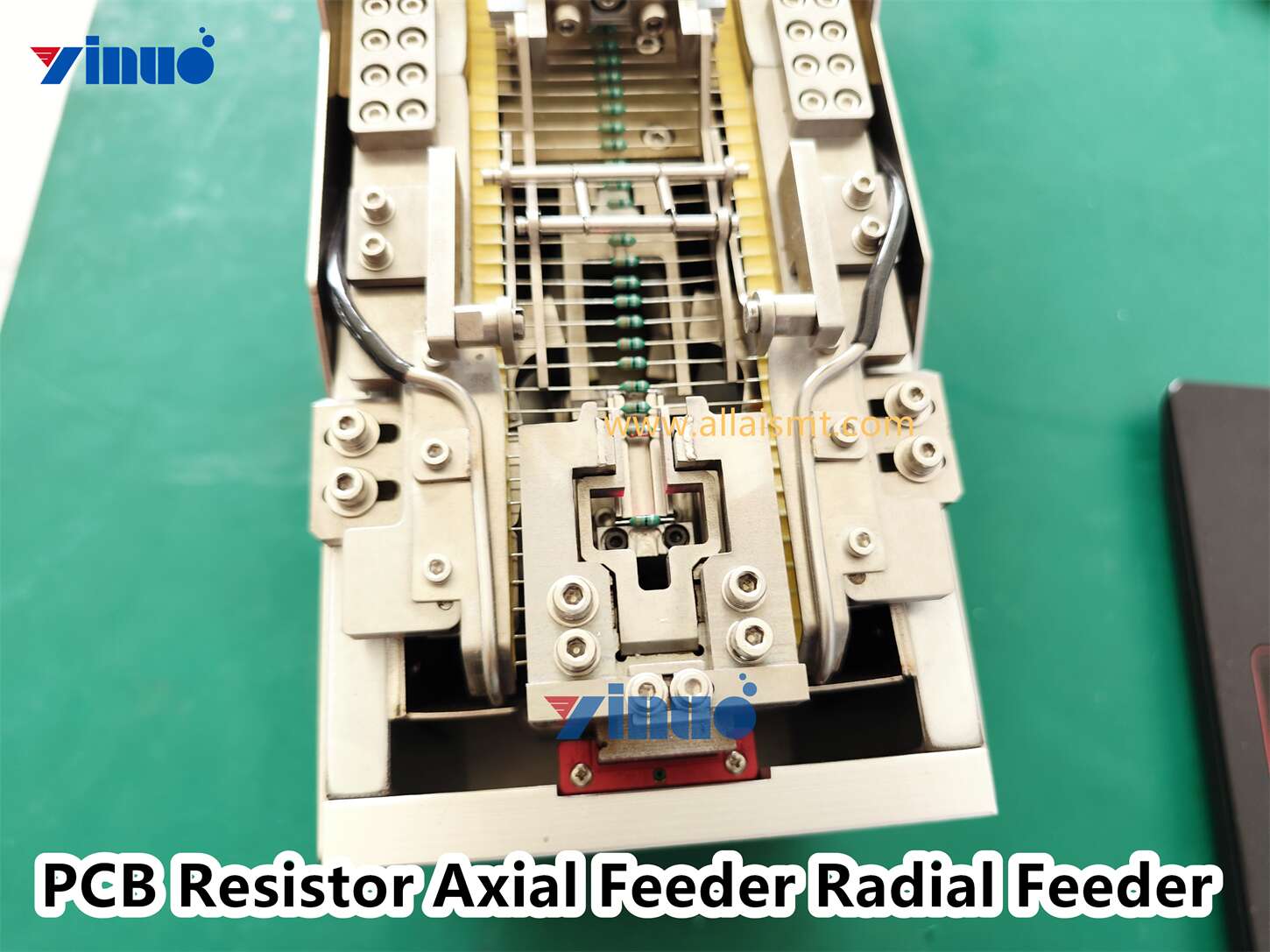

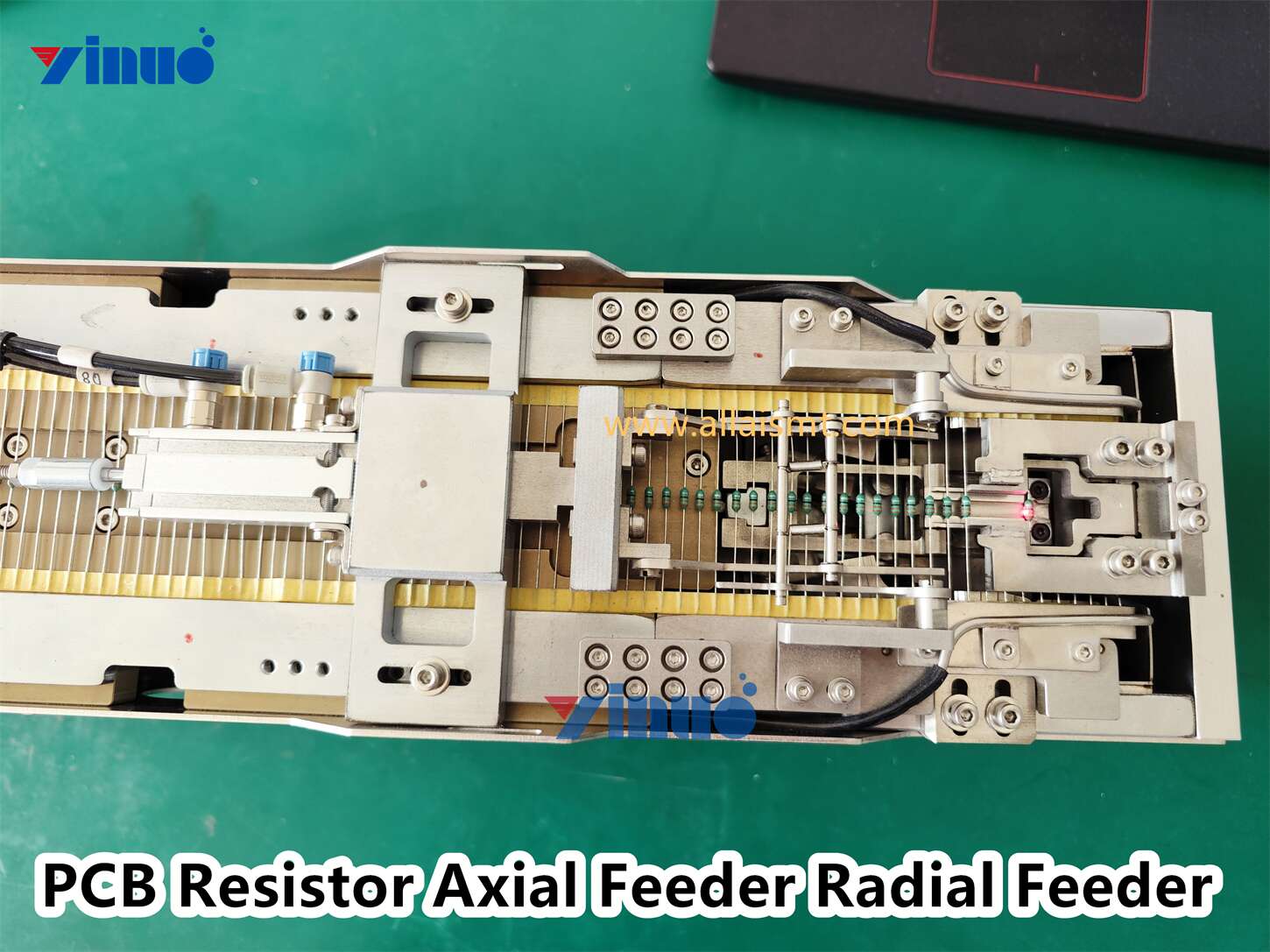

ATF-350H PCB Resistor Axial Feeder Radial Feeder

Axial feeder for SMT pick and place machines and 4-axis robots

Maximizing Efficiency with an SMT Axial Feeder

Categories: FEEDER, THT CUSTOM FEEDER

Get a Free Quote

# Maximizing Efficiency with an SMT Axial Feeder

Welcome to our blog post on maximizing efficiency with an SMT axial feeder. As the electronics industry continues to grow and evolve, it is essential to have the latest technology and equipment to remain competitive. The SMT axial feeder is a crucial component in the surface mount technology process, providing precise and efficient feeding of axial components onto printed circuit boards. In this post, we will explore the benefits of using an SMT axial feeder and how it can help increase productivity, accuracy, and overall efficiency in your manufacturing process. So, let’s dive in and discover the advantages of incorporating an SMT axial feeder into your production line.

## Maximizing Efficiency with an SMT Axial Feeder

Surface Mount Technology (SMT) is a popular method of electronic assembly in which components are mounted directly onto the surface of a printed circuit board (PCB). SMT axial feeders are an important component in this process, allowing for precise and efficient placement of axial leaded components. In this blog post, we will explore the benefits of using an SMT axial feeder and how it can help maximize efficiency in your electronic assembly process.

In conclusion, the SMT Axial Feeder is a game-changer in the electronics manufacturing industry, allowing for increased efficiency and productivity. By implementing this technology, manufacturers can reduce assembly time, minimize errors, and ultimately save costs. With its user-friendly interface and versatility, the SMT Axial Feeder is a must-have for any modern assembly line looking to maximize efficiency.

***FAQ***:

## Question 1

What is an SMT Axial Feeder?

## Answer 1

An SMT (Surface Mount Technology) Axial Feeder is a machine used in the electronics manufacturing industry to supply axial-leaded electronic components such as resistors, capacitors, and diodes to automated assembly machines for printed circuit board (PCB) production.

## Question 2

How does an SMT Axial Feeder work?

## Answer 2

An SMT Axial Feeder works by using a rotating drum to separate and align axial components into a single-file line. The components are then fed onto a track where they are picked up by a vacuum nozzle or other mechanical means and placed onto the PCB in the correct orientation.

## Question 3

What are the benefits of using an SMT Axial Feeder?

## Answer 3

Using an SMT Axial Feeder can increase efficiency and accuracy in the PCB assembly process by automating the component feeding process. This reduces the need for manual labor and ensures that components are placed correctly on the PCB. Additionally, SMT Axial Feeders can handle a large volume of components and can be easily integrated into existing assembly lines.

## Question 4

What types of components can be handled by an SMT Axial Feeder?

## Answer 4

An SMT Axial Feeder can handle a variety of axial components including resistors, capacitors, diodes, and inductors. However, it may not be suitable for larger components or those with unusual shapes or sizes.

## Question 5

How can the use of an SMT Axial Feeder improve production efficiency?

## Answer 5

The use of an SMT Axial Feeder can improve production efficiency by reducing the time and labor required for manual component feeding. Additionally, it can help to reduce errors and improve accuracy in component placement on the PCB. This can result in faster production times and higher quality products.

## Question 6

What factors should be considered when selecting an SMT Axial Feeder?

## Answer 6

When selecting an SMT Axial Feeder, factors to consider include the type and volume of components to be handled, the required speed and accuracy of the feeder, compatibility with existing assembly equipment, ease of maintenance and repair, and overall cost and ROI.

## Question 7

What are some common issues that can arise when using an SMT Axial Feeder?

## Answer 7

Common issues that can arise when using an SMT Axial Feeder include component jams, misaligned components, and mechanical failures. These issues can be mitigated through proper maintenance and calibration of the feeder, as well as regular cleaning and inspection of the feeder components.

## Question 8

How can companies ensure the optimal performance of their SMT Axial Feeder?

## Answer 8

To ensure optimal performance of an SMT Axial Feeder, companies should implement a regular maintenance and calibration schedule for the feeder. This may include cleaning and inspection of components, lubrication of moving parts, and replacement of worn or damaged parts. Additionally, operators should receive proper training on the use and maintenance of the feeder.

## Question 9

Are there any alternatives to using an SMT Axial Feeder?

## Answer 9

Yes, there are alternative methods for feeding axial components onto a PCB including manual insertion, tape and reel feeders, and stick feeders. However, these methods may not be as efficient or accurate as using an SMT Axial Feeder.

## Question 10

What is the future of SMT Axial Feeders in the electronics manufacturing industry?

## Answer 10

As the electronics manufacturing industry continues to evolve, the use of SMT Axial Feeders is likely to become more widespread. This is due to their ability to increase efficiency and accuracy in the PCB assembly process, as well as their compatibility with other automated assembly equipment. Additionally, advancements in feeder technology may lead to even greater efficiency and performance in the future.