Integrating Label Feeders with Barcode Systems: A Perfect Match

In the modern manufacturing landscape, efficiency and accuracy are paramount. The integration of label feeders with barcode systems represents a synergy that enhances both these aspects, resulting in streamlined operations and improved productivity. This article explores the benefits of combining label feeders with barcode systems and how this integration creates a perfect match for various industries.

The Role of Label Feeders and Barcode Systems

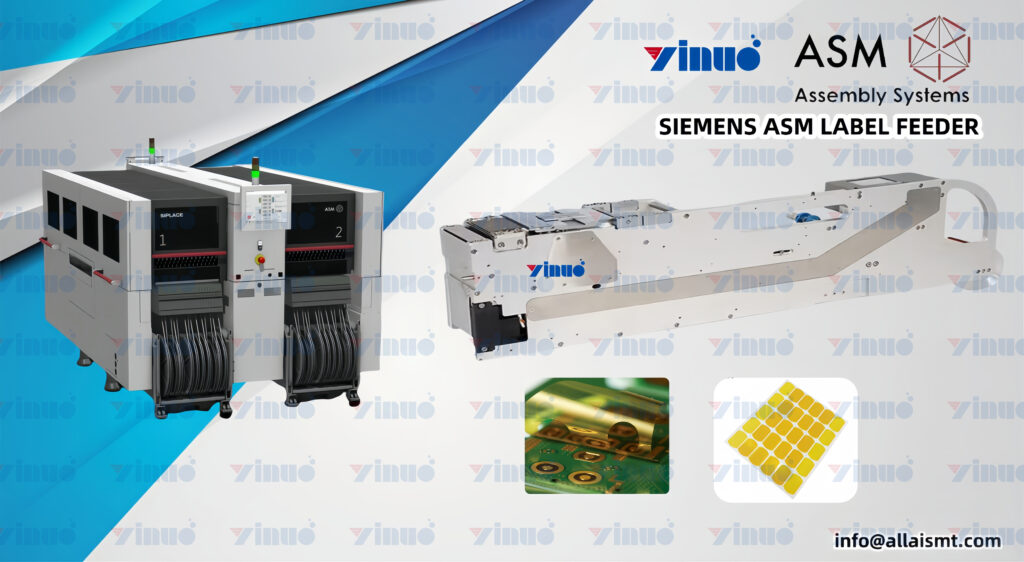

Label Feeders: These automated systems are designed to apply labels quickly and accurately to products. By reducing manual intervention, label feeders increase speed and consistency in the labeling process, ensuring each product is correctly labeled without errors.

Barcode Systems: Barcodes encode product information into a visual pattern readable by machines. They are essential for tracking inventory, managing supply chains, and ensuring accurate data entry. Barcode systems consist of barcode printers and scanners that work together to print and read barcodes.

Benefits of Integration

- Enhanced EfficiencyIntegrating label feeders with barcode systems significantly boosts operational efficiency. Automated label application combined with precise barcode printing and scanning reduces the time and effort required for labeling and tracking products. This integration streamlines the workflow, allowing manufacturers to handle higher volumes with less manual labor.

- Improved Accuracy and ConsistencyManual labeling is prone to human error, leading to misaligned or incorrect labels. By automating the process, label feeders ensure that each label is applied accurately. When paired with barcode systems, this accuracy extends to data entry and inventory management. Barcodes eliminate the need for manual data entry, reducing the risk of errors and ensuring that product information is consistently accurate.

- Real-Time Tracking and Inventory ManagementBarcodes enable real-time tracking of products throughout the supply chain. When labels with barcodes are applied by label feeders, each product can be scanned at various points in the production and distribution process. This real-time data collection provides manufacturers with up-to-date information on inventory levels, product locations, and production status, facilitating better decision-making and inventory management.

- Cost SavingsThe automation and precision provided by integrated label feeders and barcode systems lead to significant cost savings. Reduced labor costs, fewer labeling errors, and minimized product recalls contribute to overall cost efficiency. Additionally, the ability to track inventory in real-time helps optimize stock levels, reducing the costs associated with overstocking or stockouts.

- Compliance and Quality ControlMany industries, such as pharmaceuticals, food and beverage, and electronics, have stringent labeling and tracking requirements. Integrating label feeders with barcode systems ensures compliance with industry regulations by providing accurate and traceable labeling. This integration also enhances quality control by enabling detailed tracking of each product’s journey through the supply chain.

- ScalabilityAs manufacturing demands grow, the scalability of integrated label feeders and barcode systems becomes a significant advantage. These systems can handle increased production volumes without compromising on speed or accuracy. This scalability is crucial for manufacturers looking to expand operations or enter new markets while maintaining high standards of efficiency and quality.

Implementation Considerations

- Compatibility and IntegrationEnsure that label feeders and barcode systems are compatible and can be seamlessly integrated into existing production lines. Choose systems that support standard communication protocols and can be easily configured to work together.

- Training and SupportProvide adequate training for staff to operate and maintain the integrated systems. Regular support and maintenance are essential to keep the systems running smoothly and to address any issues that arise.

- Customization and FlexibilityOpt for systems that offer customization and flexibility to meet specific production requirements. Advanced label feeders and barcode systems can be programmed for different label sizes, barcode formats, and application patterns, catering to diverse manufacturing needs.

- Data ManagementImplement robust data management solutions to handle the data generated by barcode scanning. Ensure that the data is accurately recorded, stored, and analyzed to support inventory management and decision-making processes.

Conclusion

The integration of label feeders with barcode systems represents a powerful combination that enhances manufacturing efficiency, accuracy, and productivity. By automating label application and ensuring precise barcode printing and scanning, manufacturers can achieve significant cost savings, improved quality control, and real-time inventory management. This integration is a perfect match for industries looking to optimize their operations, maintain compliance, and scale their production capabilities. Investing in this technology is a strategic move that offers long-term benefits and a competitive edge in the modern manufacturing landscape.