Enhancing Production Lines with Advanced Label Feeders

In the competitive world of manufacturing, enhancing production line efficiency is essential for staying ahead. One of the key technologies driving this improvement is the advanced label feeder. These sophisticated systems automate the labeling process, offering precision, speed, and versatility. This article explores how advanced label feeders can enhance production lines, leading to increased productivity, reduced costs, and improved quality control.

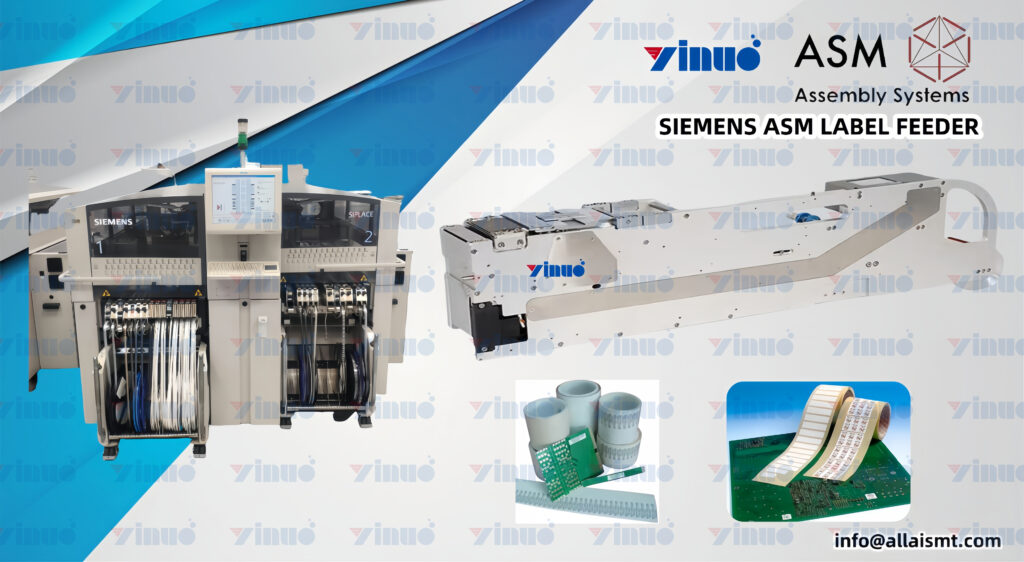

What Are Advanced Label Feeders?

Advanced label feeders are automated machines designed to apply labels to products swiftly and accurately. Unlike traditional manual labeling, these systems integrate seamlessly with production lines, ensuring consistent and precise label application. They can handle a variety of label types and sizes, making them suitable for diverse industrial applications.

Key Benefits of Advanced Label Feeders

- Increased Production SpeedAdvanced label feeders significantly speed up the labeling process. Manual labeling is time-consuming and can create bottlenecks in the production line. Automated feeders, however, can label hundreds of products per minute, dramatically increasing throughput and enabling manufacturers to meet high demand and tight deadlines more efficiently.

- Enhanced Accuracy and ConsistencyPrecision is critical in labeling, especially for compliance with industry standards and regulations. Advanced label feeders ensure that each label is applied correctly, reducing the risk of misaligned or incorrect labels. This consistency enhances the overall quality of the products and maintains brand integrity.

- Cost EfficiencyWhile the initial investment in advanced label feeders may be substantial, the long-term cost savings are significant. By reducing the need for manual labor, manufacturers can lower labor costs and minimize the risk of costly labeling errors. Additionally, the increased efficiency leads to better resource utilization and lower operational costs.

- Flexibility and AdaptabilityModern label feeders are designed to handle a wide range of labeling requirements. They can accommodate different label sizes, shapes, and materials, making them highly versatile. This flexibility allows manufacturers to easily switch between products without extensive downtime, catering to diverse production needs and seasonal variations.

- Improved Quality ControlConsistent and accurate labeling is crucial for maintaining product quality. Advanced label feeders contribute to improved quality control by ensuring that every product is labeled correctly. This is particularly important in industries such as pharmaceuticals and food and beverage, where accurate labeling is essential for safety and compliance.

Impact on Production Lines

- Streamlined OperationsBy automating the labeling process, advanced label feeders streamline production lines. They integrate seamlessly with other machinery, such as conveyors and inspection systems, creating a cohesive and efficient production environment. This integration minimizes bottlenecks and ensures a smooth, continuous operation.

- Reduced DowntimeAdvanced label feeders are designed for reliability and durability. They require less maintenance compared to manual labeling processes, reducing downtime and keeping the production line running smoothly. Regular maintenance and occasional part replacements are generally sufficient to keep the feeders in optimal condition.

- ScalabilityAs production demands grow, advanced label feeders can easily scale to accommodate increased volumes. This scalability is crucial for manufacturers looking to expand their operations or enter new markets. The ability to handle higher production volumes without compromising on speed or accuracy gives manufacturers a competitive edge.

- Integration with TechnologyAdvanced label feeders can be integrated with other technological solutions such as barcode systems and RFID tagging. This integration enhances traceability and inventory management, providing real-time data on product movement and inventory levels. Such technological synergy improves overall supply chain efficiency.

Implementation Considerations

- CompatibilityEnsure that the advanced label feeders are compatible with existing production line equipment. This includes checking for compatibility with conveyors, barcode systems, and other machinery.

- Training and SupportProvide comprehensive training for staff to operate and maintain the label feeders. Regular support and maintenance are essential to address any issues promptly and keep the systems running smoothly.

- CustomizationOpt for label feeders that offer customization options to meet specific production requirements. This includes the ability to handle different label sizes, materials, and application patterns.

- Data IntegrationImplement robust data integration solutions to manage the information generated by the labeling process. This includes tracking label application, monitoring production metrics, and ensuring accurate data entry.

Conclusion

Advanced label feeders are a vital component for enhancing production lines in modern manufacturing. They offer increased speed, accuracy, cost efficiency, and flexibility, all of which contribute to streamlined operations and improved product quality. By investing in advanced label feeders, manufacturers can achieve significant long-term benefits, including higher productivity, reduced operational costs, and a competitive edge in the market. As technology continues to evolve, the role of advanced label feeders in driving efficiency and innovation in production lines will only become more critical.