# SMT printer Temperature and Humidity Controlled Chillers

## SMT printer Temperature and Humidity Controlled Chillers

In the world of Surface Mount Technology (SMT) printing, precision is key. The slightest variation in temperature or humidity can affect the quality of the printed circuit board (PCB), leading to costly rework or even product failure. That’s why it’s essential to have a reliable temperature and humidity control system in place for your SMT printer.

One of the most effective solutions for temperature and humidity control in SMT printing is the use of chillers. These are specialized cooling units that are designed to regulate air temperature and humidity to precise levels, ensuring optimal conditions for the printing process.

With a chiller system in place, you can maintain a consistent temperature and humidity level throughout your production facility, which is essential for high-quality PCB manufacturing. In this article, we’ll take a closer look at how SMT printer temperature and humidity controlled chillers work and why they’re an essential part of any SMT printing operation.

***FAQ***:

The blog discusses the use of Temperature and Humidity Controlled Chillers for SMT printers, which are designed to regulate the air temperature and humidity levels in the printing environment.

## What are Temperature and Humidity Controlled Chillers for SMT printers?

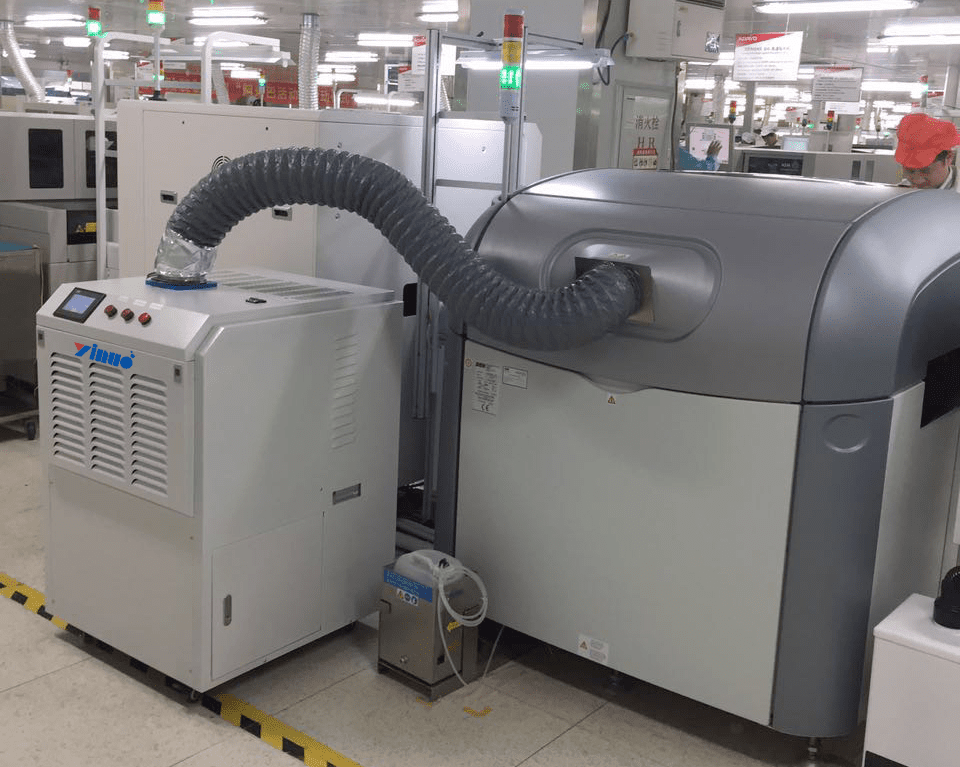

Temperature and Humidity Controlled Chillers for SMT printers are specialized units that are used to regulate the air temperature and humidity levels in the printing environment. These units are installed near the SMT printer and are capable of maintaining a constant temperature and humidity level, regardless of external conditions.

## How do Temperature and Humidity Controlled Chillers work with SMT printers?

Temperature and Humidity Controlled Chillers work by drawing in air from the surrounding environment, filtering it, and then cooling or heating it to the desired temperature. The chiller then passes the air through a humidifier, which adds moisture to the air to maintain the desired humidity level. The conditioned air is then delivered to the SMT printer through ducts or vents, creating a controlled printing environment.

## What are the benefits of using Temperature and Humidity Controlled Chillers for SMT printers?

There are several benefits of using Temperature and Humidity Controlled Chillers for SMT printers, including:

1. Improved print quality – By maintaining a consistent temperature and humidity level, the printing process is more stable and reliable, resulting in higher quality prints.

2. Increased productivity – With a controlled printing environment, there is less downtime due to equipment failure or environmental fluctuations, allowing for increased productivity.

3. Cost savings – By reducing the need for manual adjustment of the printing environment, as well as reducing equipment failure and maintenance costs, Temperature and Humidity Controlled Chillers can save money in the long run.

4. Environmental control – By regulating the temperature and humidity levels in the printing environment, Temperature and Humidity Controlled Chillers can help prevent damage to sensitive electronic components, as well as reduce the risk of electrostatic discharge (ESD) damage.

| 1.Cooling capacity: 2700W |

| 2.Power frequency: 220V-50HZ or 110v-50HZ |

| 3.Use power: 3.6KW |

| 4.Air outlet mode: right suction, top outlet/left outlet |

| 5.Control method: microcomputer automatic control |

| 6.Cooling air volume: 400m³/H |

| 7.Refrigerant: R470C |

| 8.Body size: 975*560*1040mm |

| 9.Temperature control range: 16-30°C |

| 10.Humidity control range: 40-70% |

| 11.Display mode: color LCD touch screen |

| 12.The power cord comes with leakage protection:yes |

| 13.Automatic diagnosis of faults: yes |

| 14.Current ambient temperature and humidity display |

| 15.Hitachi compressor, super quiet |

| 16.Exquisite appearance, universal wheels turn freely |

| 17.Schneider Electric Systems |