# Increase Your PCB Assembly Efficiency with a Press Fit Machine

Are you tired of spending long hours manually assembling printed circuit boards (PCBs)? Well, we have good news for you. In this article, we will introduce you to the latest innovation in PCB assembly technology – the press fit machine. By using a press fit machine, you can significantly increase your assembly efficiency and save time and money in the process. So, let’s dive into the world of PCB assembly and explore the benefits of using a press fit machine.

<iframe width=”560″ height=”315″ src=”https://www.youtube.com/embed/ajPNavmbnG0″ title=”YouTube video player” frameborder=”0″ allow=”accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share” allowfullscreen></iframe>

## Increase Your PCB Assembly Efficiency with a Press Fit Machine

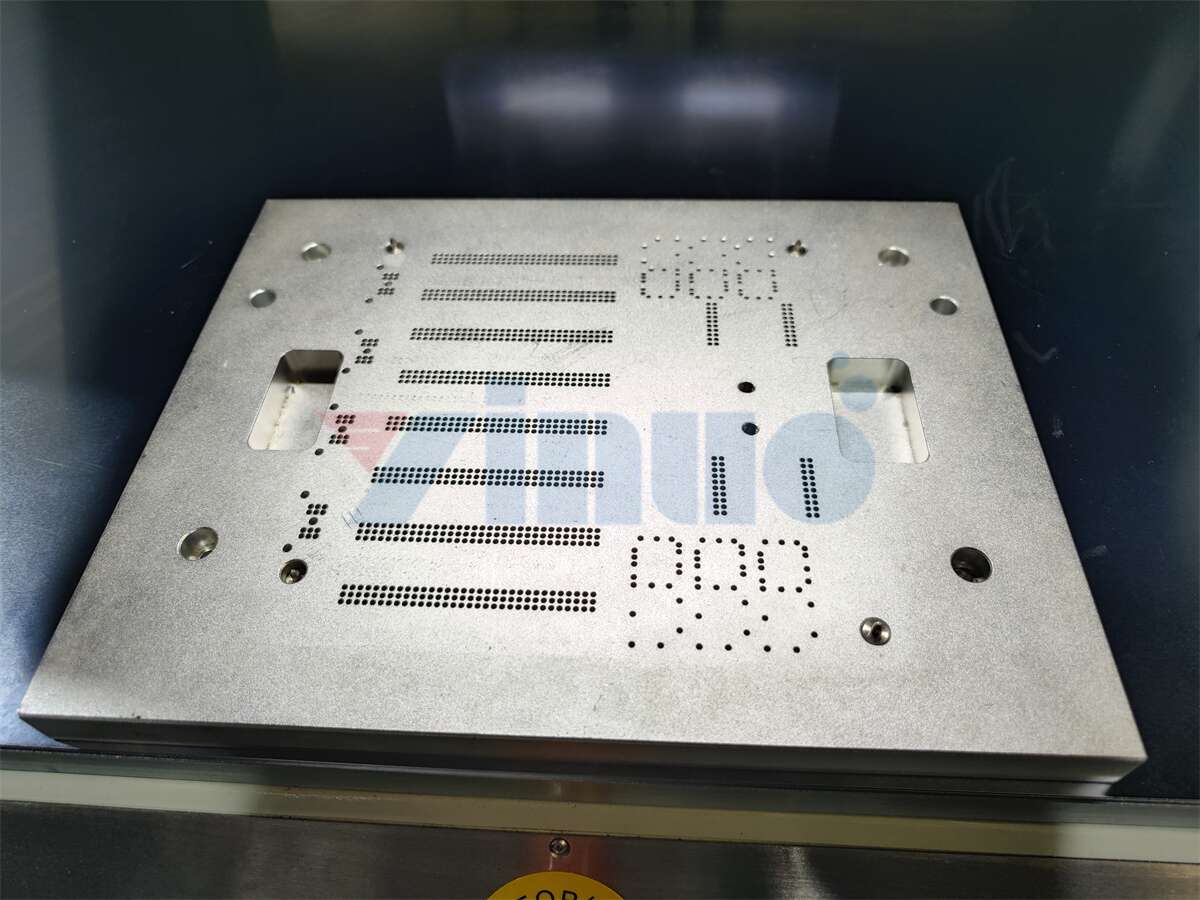

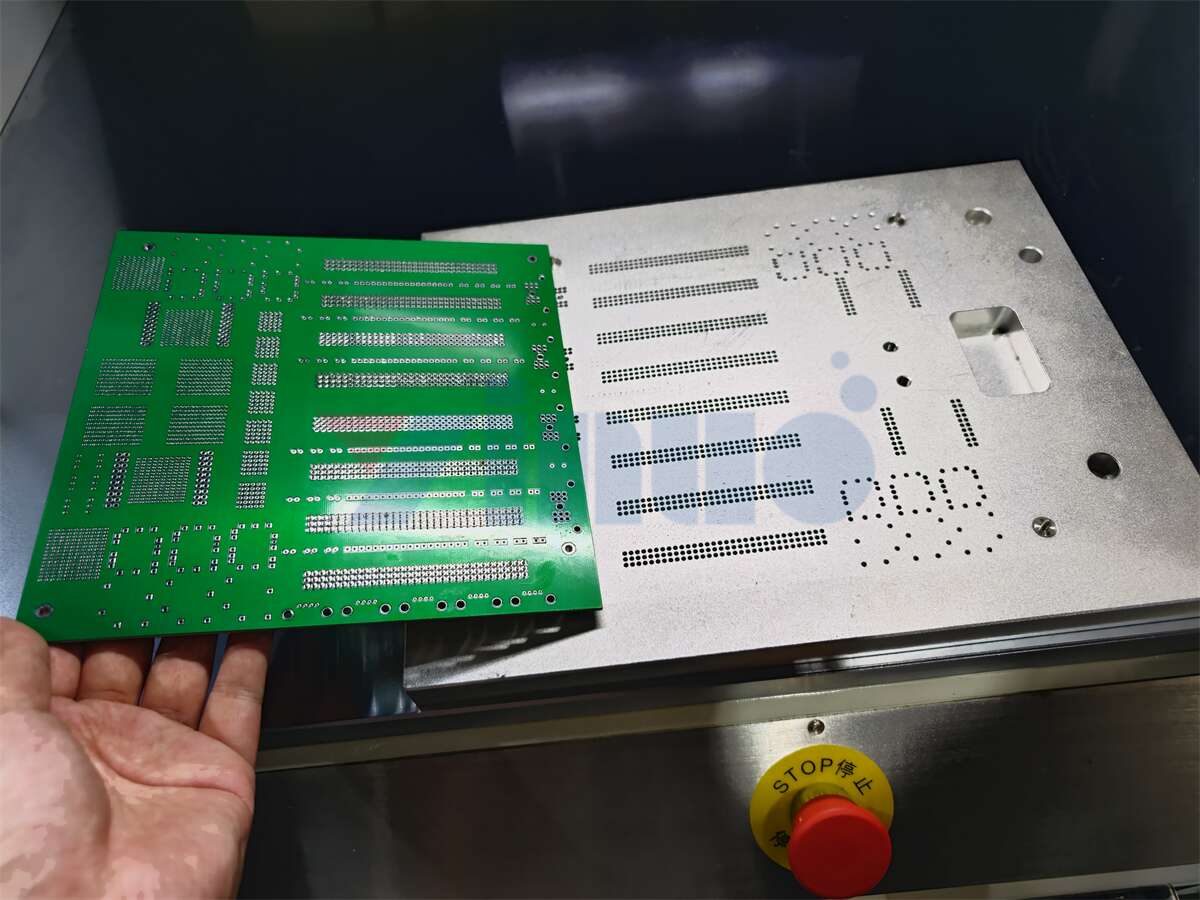

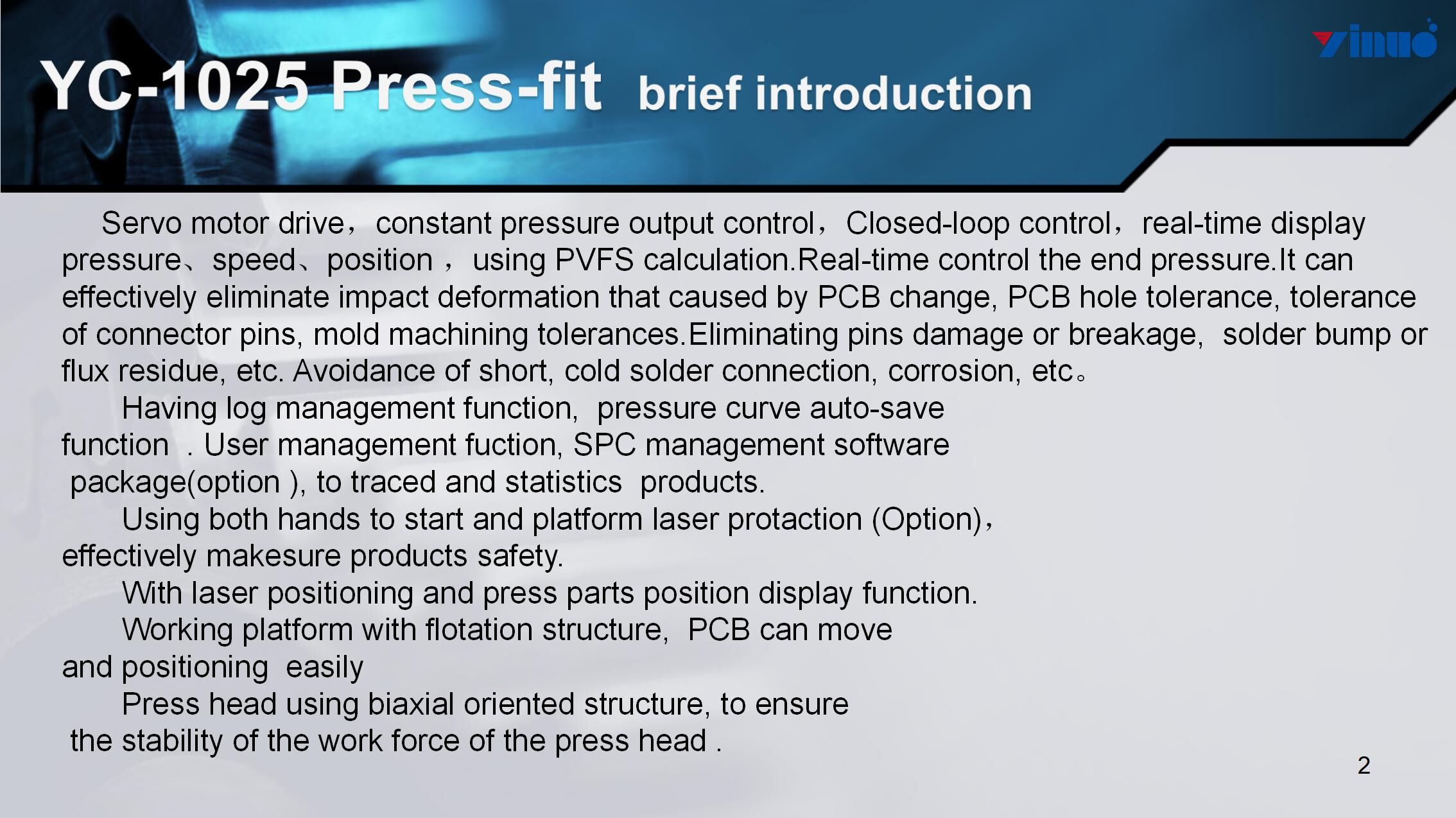

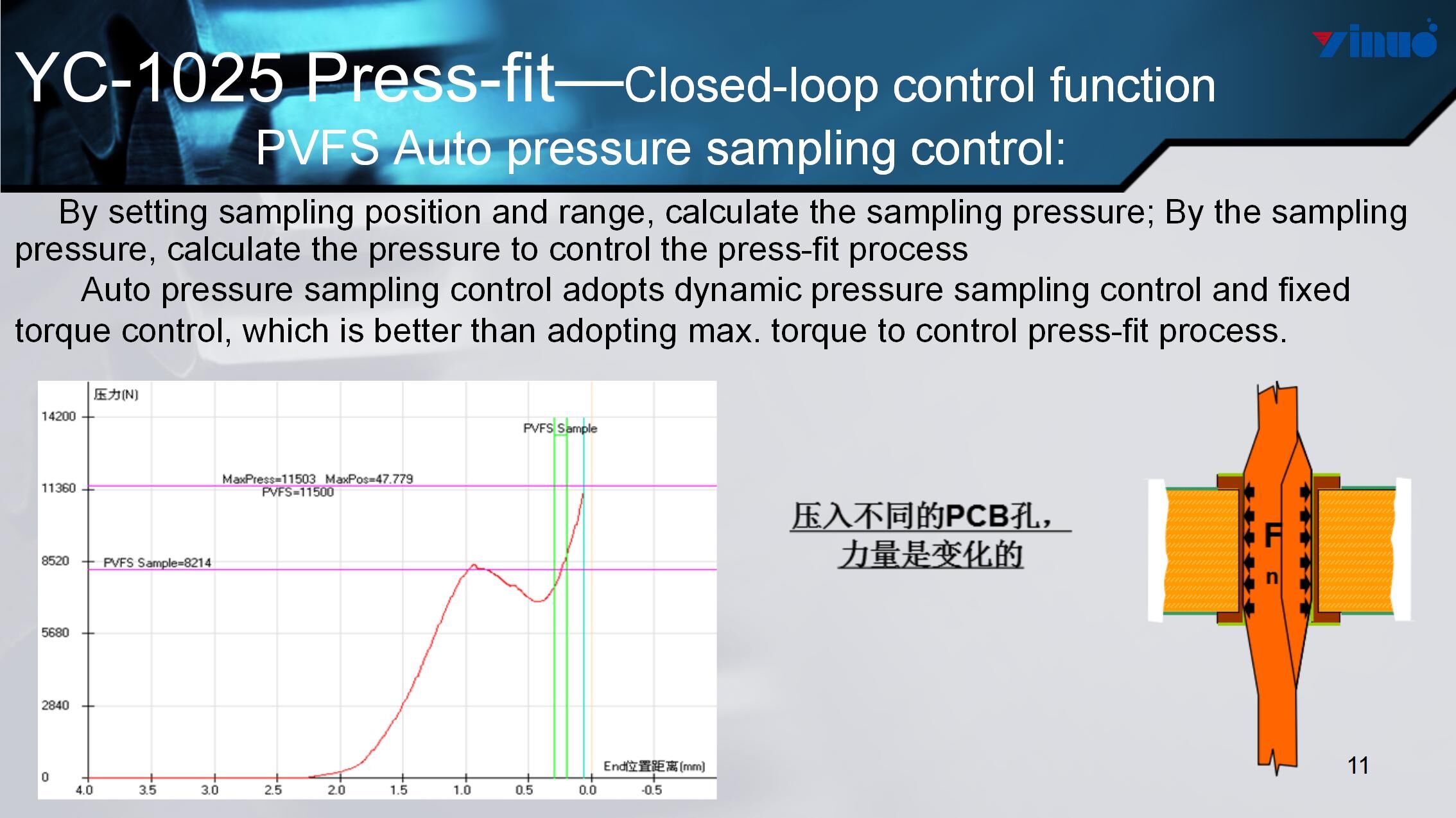

PCB assembly can be a complex and time-consuming process, but utilizing a press fit machine can increase efficiency and accuracy in your assembly line. A press fit machine is designed to securely insert components into a circuit board without the need for soldering. This not only reduces the risk of damage to the board and components but also speeds up the assembly process.

One of the main advantages of using a press fit machine is that it eliminates the need for soldering, which can be a time-consuming and error-prone process. With soldering, there is always a risk of overheating the board or damaging components, which can lead to costly repairs and delays in production. By using a press fit machine, you can avoid these issues and ensure that your components are securely inserted into the board.

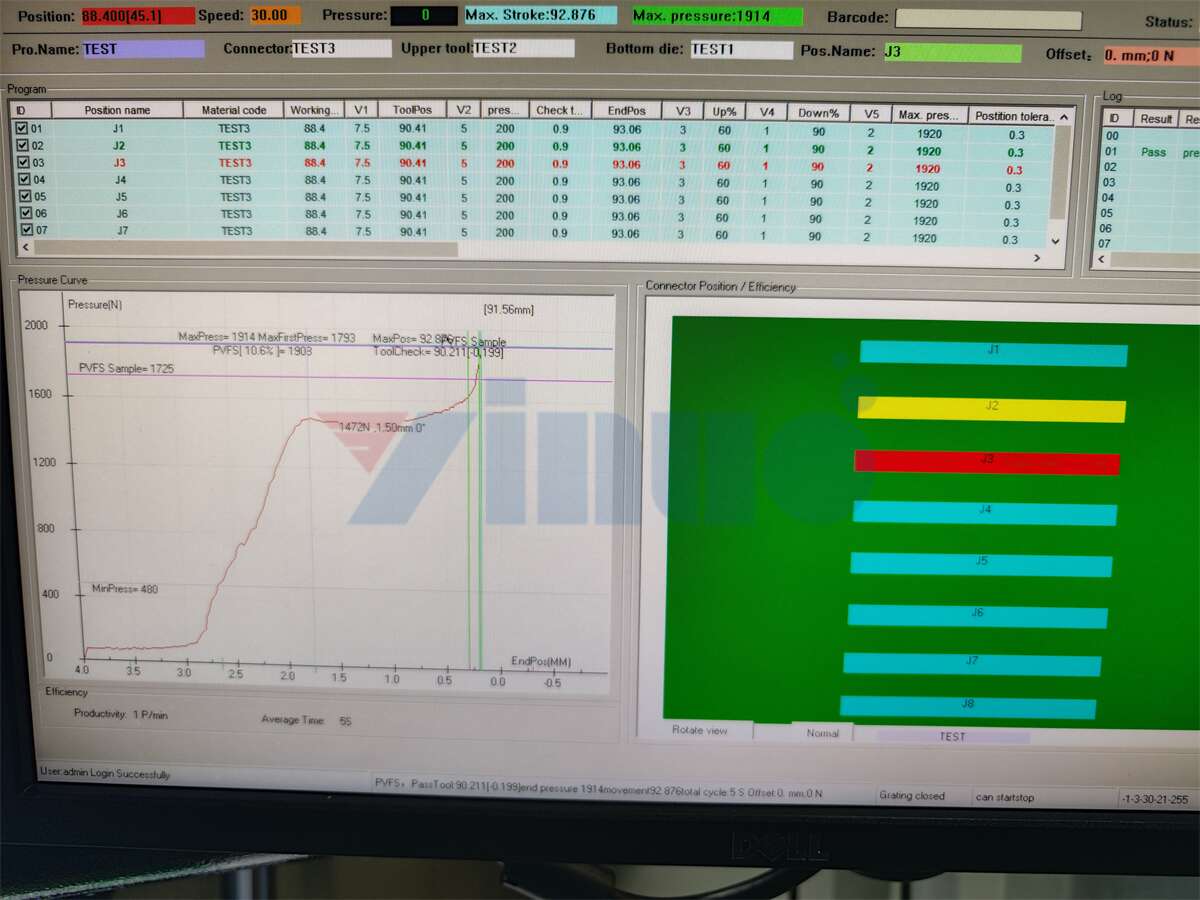

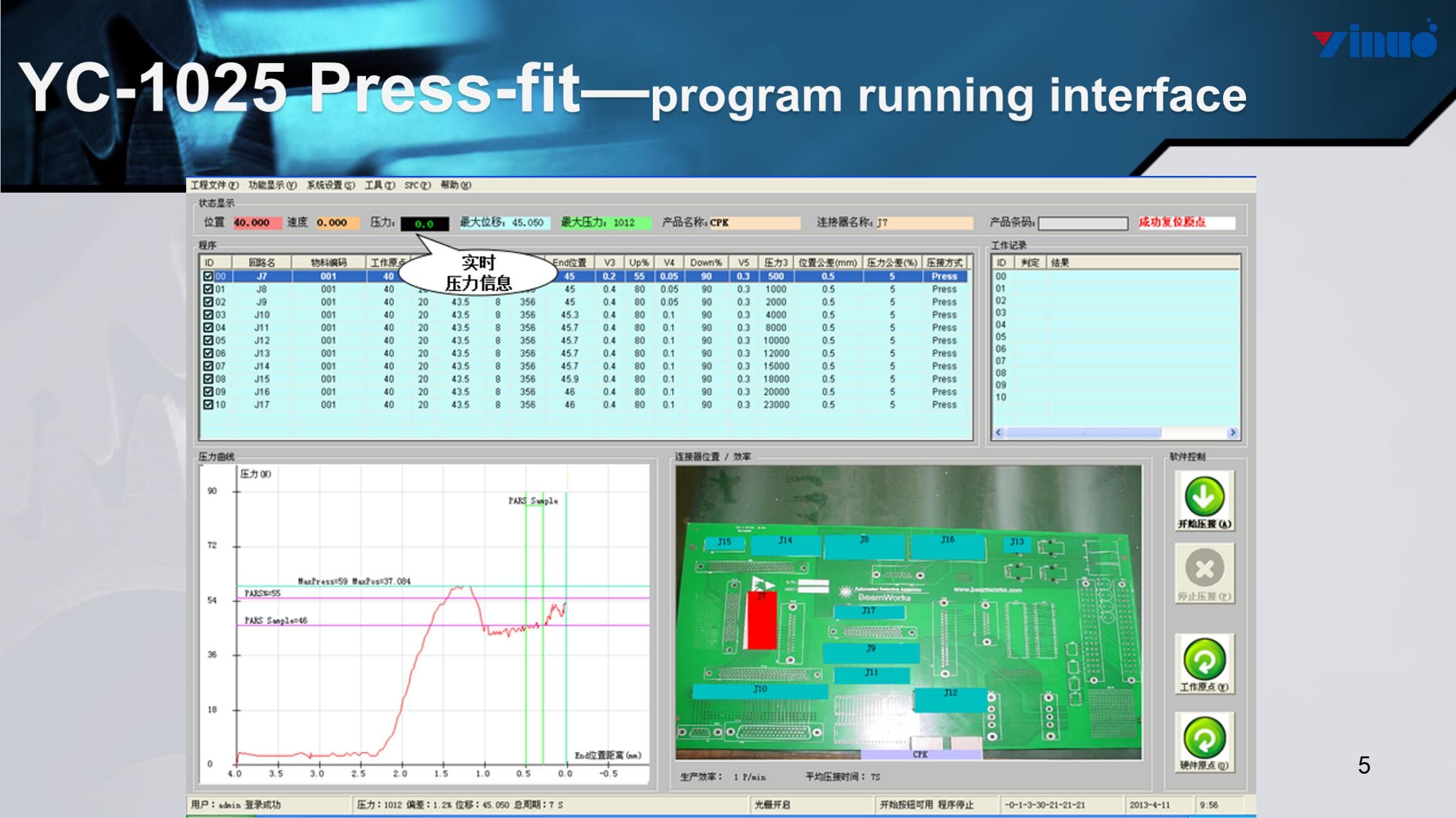

Another advantage of using a press fit machine is that it can help increase the accuracy of your assembly line. The machine is designed to precisely align and insert components into the board, which reduces the risk of misalignments or errors in placement. This not only improves the overall quality of your products but can also reduce the need for rework or repairs.

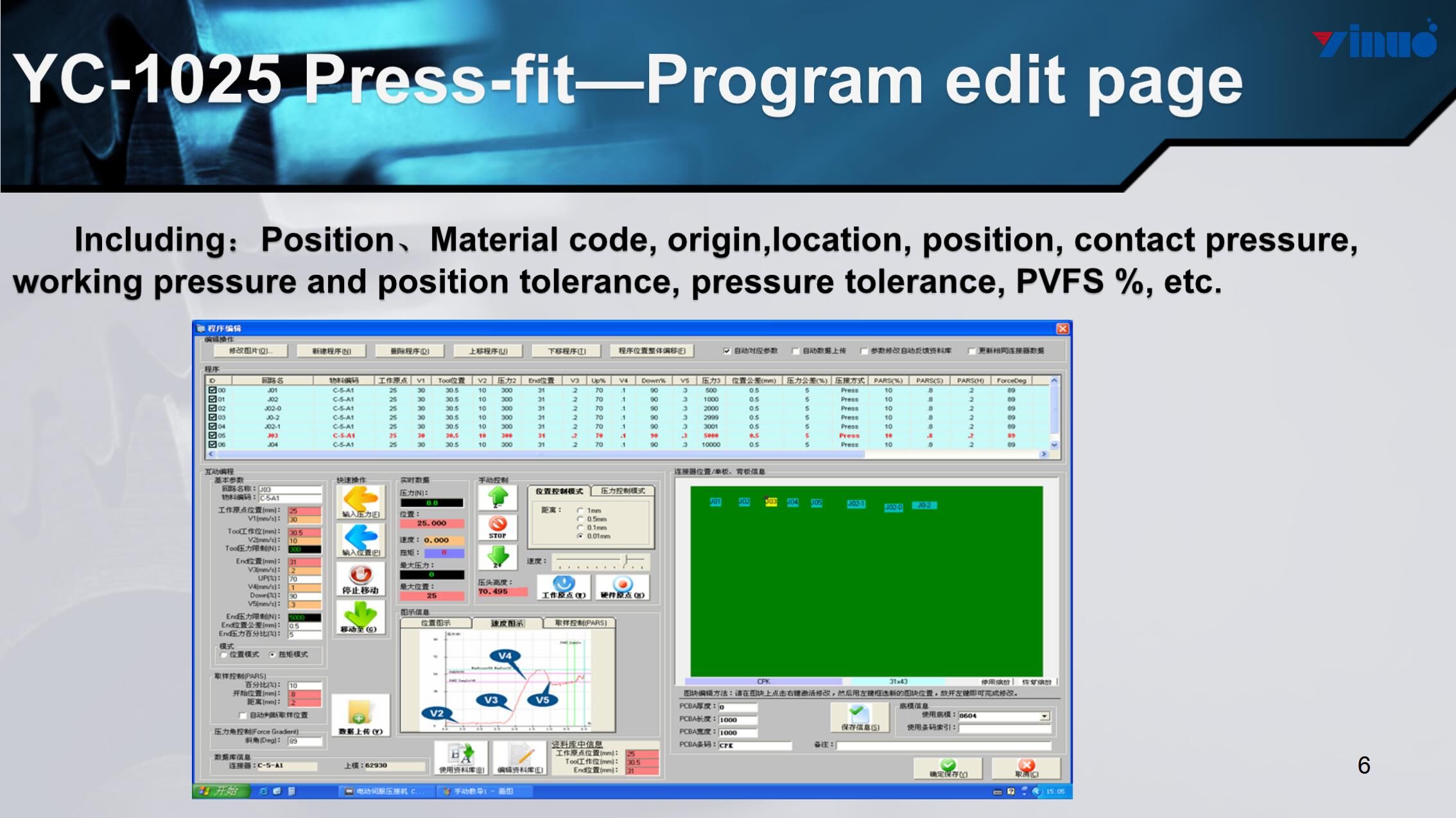

Additionally, press fit machines can be programmed to work with a variety of component sizes and shapes, making them versatile tools for PCB assembly. They can also handle high volumes of components quickly and efficiently, further increasing productivity and reducing assembly time.

Overall, incorporating a press fit machine into your PCB assembly line can provide numerous benefits, including increased efficiency, accuracy, and versatility. By reducing the need for soldering and improving component alignment, a press fit machine can help streamline your assembly process and improve the quality of your products.

In conclusion, using a press fit machine can greatly increase the efficiency of PCB assembly. It reduces the need for soldering and allows for easier customization of designs. By implementing this technology, manufacturers can streamline their production processes and deliver high-quality products to customers in less time.

***FAQ***:

## Question 1

What is a press fit machine?

## Answer 1

A press fit machine is a piece of equipment used in PCB assembly that inserts components into pre-drilled holes on a printed circuit board using mechanical force rather than soldering.

## Question 2

How does a press fit machine work?

## Answer 2

A press fit machine uses a combination of hydraulic or pneumatic pressure and precision tooling to insert components into pre-drilled holes on a PCB. The machine applies force to the component, pressing it into the hole and creating a secure connection without the need for solder.

## Question 3

What are the benefits of using a press fit machine in PCB assembly?

## Answer 3

Using a press fit machine can increase efficiency and accuracy in PCB assembly by eliminating the need for soldering and reducing the risk of damage to components from heat. It also allows for easier rework and repair of PCBs and can save time and cost in production.

## Question 4

What types of components can be inserted using a press fit machine?

## Answer 4

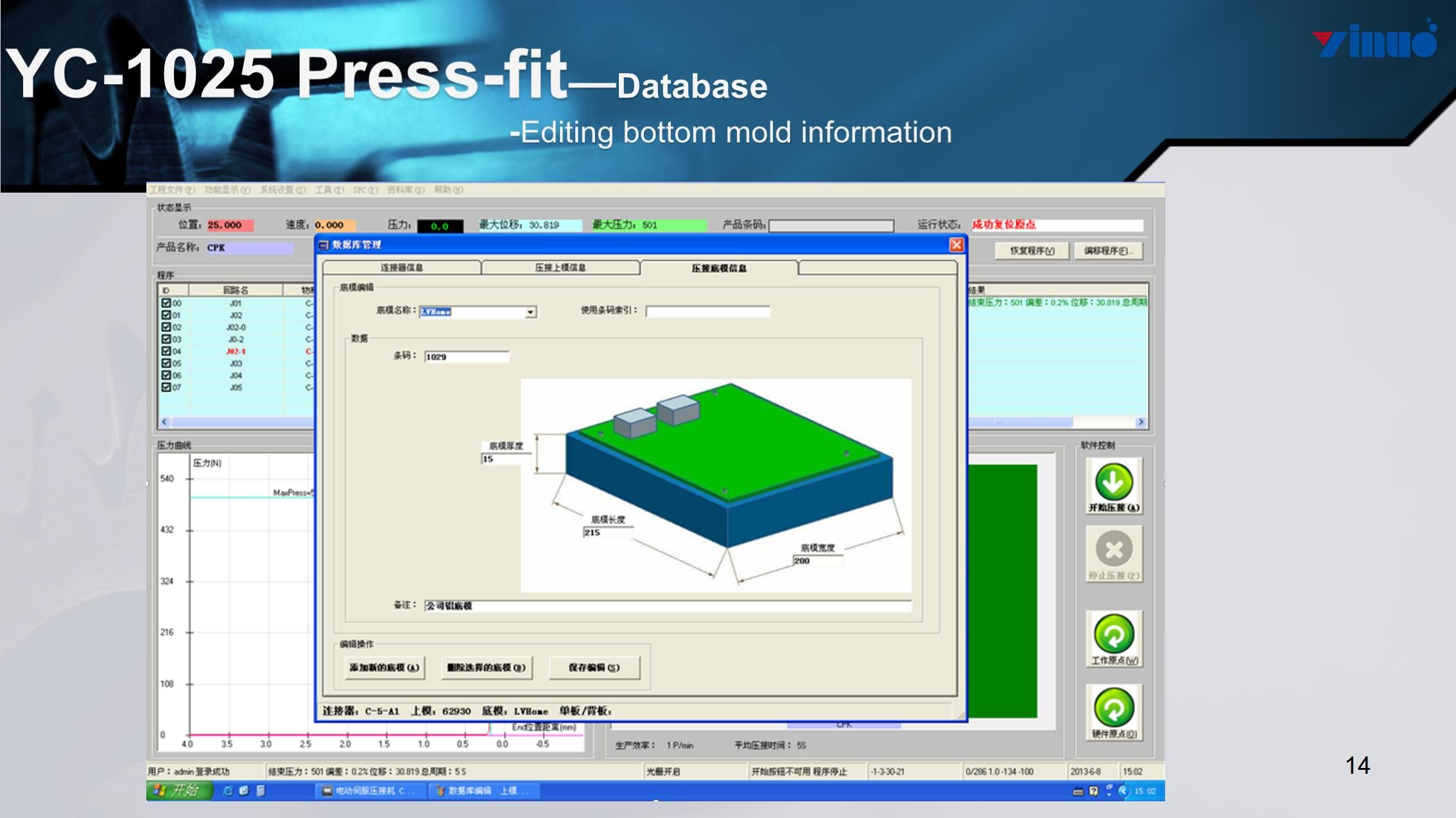

A press fit machine can be used to insert various types of components such as connectors, headers, sockets, and pins with different shapes and sizes, making it a versatile tool in PCB assembly.

## Question 5

What factors should be considered when selecting a press fit machine?

## Answer 5

When selecting a press fit machine for PCB assembly, factors such as the type and size of components being used, production volume, and required precision should be considered. Other factors include machine speed, ease of use, maintenance requirements, and cost.

## Question 6

What are some common challenges in using a press fit machine?

## Answer 6

Some common challenges in using a press fit machine include component misalignment, incorrect insertion depth, and component damage due to excessive force or improper tooling. Proper machine setup, calibration, and maintenance can help mitigate these challenges.

## Question 7

What are some best practices for using a press fit machine?

## Answer 7

Best practices for using a press fit machine include selecting the appropriate tooling for each component, ensuring proper alignment and insertion depth, performing regular maintenance and calibration, and monitoring the machine for any signs of malfunction or wear.

## Question 8

What are some alternatives to using a press fit machine in PCB assembly?

## Answer 8

Alternatives to using a press fit machine in PCB assembly include soldering components onto the PCB manually or using automated pick-and-place machines that use solder paste and reflow ovens. Each method has its own benefits and limitations depending on the specific production requirements and types of components being used.

## Question 9

What industries commonly use press fit machines in their PCB assembly process?

## Answer 9

Industries such as automotive, aerospace, telecommunications, and consumer electronics commonly use press fit machines in their PCB assembly process due to the high volume and complexity of components required in their products.

## Question 10

What is the future outlook for press fit machines in PCB assembly?

## Answer 10

The future outlook for press fit machines in PCB assembly is positive, with advancements in technology and increased demand for faster and more efficient production methods driving innovation in the industry. New developments such as AI-powered machine learning and robotics are also expected to enhance the capabilities and versatility of press fit machines.