1. Earnestly accept the operation training of the equipment manufacturer, and be able to operate wave soldering independently and skillfully according to the chapter. 2. Maintenance of the spray system: During wave soldering, the nozzle should be cleaned with alcohol every 8 hours, and the nozzle should be cleaned when it is out of service. […]

Tag Archives: Pick and place machine

The metal base copper clad laminate is generally composed of a metal substrate, an insulating dielectric layer and a conductive layer (usually copper foil). That is, one or both sides of the metal substrate with the surface treated are covered with insulating medium and copper foil, and then composited by hot pressing . (1) Classification […]

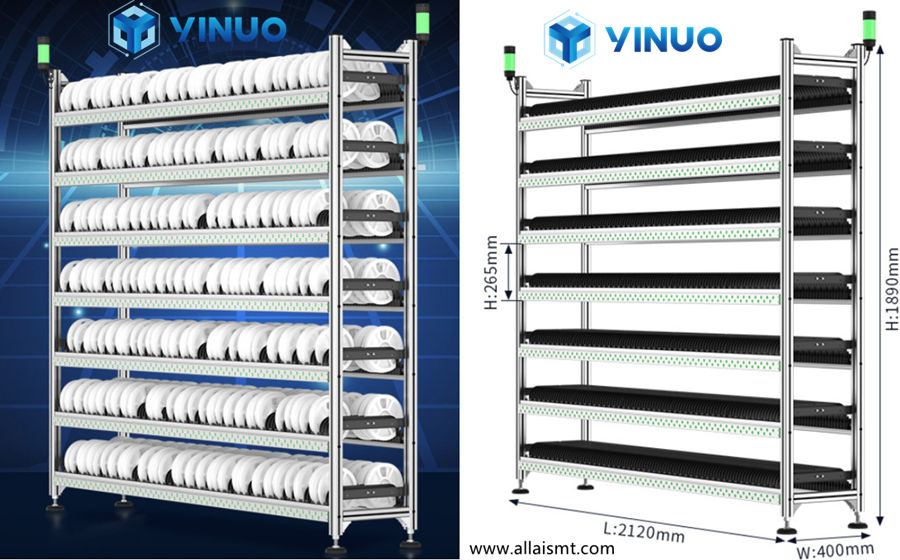

-The delivery time is reduced from two hours to 15 minutes, and the efficiency is increased by 8 times – each shelf can be unordered storage of 1400 trays of materials, inventory area can be saved by 40% – the location of each material can be checked quickly, and the inventory time can be reduced […]

The intelligent warehousing system integrates with the ERP system, MES system, etc., to accurately realize the distribution of work order materials according to the station information; the SMT intelligent warehousing system and the placement machine data interconnection, realize the automatic data of the end of the production line when the materials are returned to the […]

1. Why is the PCB multilayer circuit board required to be very flat: In the automated assembly line, if the PCB multi-layer board is not flat, it will cause inaccurate positioning, components cannot be inserted into the holes and surface mount pads of the board, and even the automatic plug-in assembly machine will be damaged. […]

The quality and reliability of surface mount products mainly depend on the manufacturability and reliability of components, electronic process materials, process design and assembly processes. In order to successfully assemble SMT products, on the one hand, the quality of electronic components and process materials needs to be strictly controlled, that is, incoming inspection; on the […]